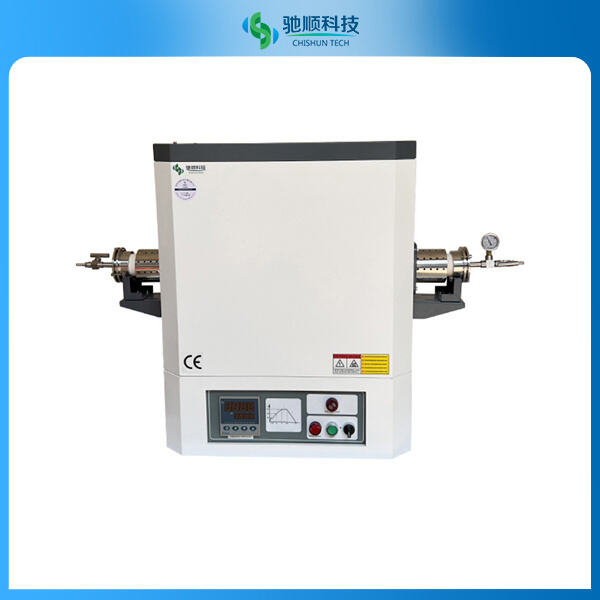

Ceramic tubes for better furnace performance. Nanjing Chishun ceramic sintering furnace are everywhere but we should notice the vital application of ceramic tubes in our lives.

Ceramic tubes are made from clay specially formulated for very high temperatures and fired at a higher temperature than regular bricks to create strong, barely-permeable tube constructions that can withstand exceedingly-hot temperatures without any damage. Nanjing Chishun tube furnace is available in a wide range of designs, shapes and sizes these tubes enable multiple customization options to fulfill diverse industry needs. Because of their superior heat insulation, they are primarily used in industrial settings like ovens, kilns and furnaces. It is an interesting potential to be able to cut down energy consumption.

Ceramic tubes have many features. Nanjing Chishun tubular furnace has exceptional thermal shock resistance is a feature that allows them to withstand inconspicuous temperature changes without the fear of cracking or breaking. Applications for these tubes are wide-ranging, from heating food in a microwave to smelting metal ores in furnaces. They are lightweight and easily usable for valves both industrial and domestic.

Innovations in the ceramic tube sector continuously focus on new design and materials that will improve product efficiency or offer a better performance. A breakthrough in laboratory tube furnace makes the most of advanced ceramics which are even more potent, lasting and thermal shock resistance capable. These ceramic tubes receive some new innovation. They now have been coated with specially-made coatings which increases their resistance to high temperatures and improves insulation properties to an even greater extent - leading towards further reduction in energy costs.

The most important thing while using ceramic tubes is to ensure their security. It is important to follow the instructions from your manufacturer and having proper safety protocols in place. Tubes are typically restrained within the furnace or oven using clamps, fasteners-and/or other appropriate installation techniques. A high temperature tube furnace must be properly positioned so it does not touch other parts to have a chance at surviving without damage. A protective heat shield can also be used to increase the safety.

Care Planning -Service Excellence and Quality Assurance

It is imperative to choose ceramic tubes from a leading manufacturer who will provide outstanding service and ensure quality. A good manufacturer will provide warranties, technical support and after-sales services to ensure that you get the best out of their products. These manufacturers make their ceramic tubes with the superior materials and manufacturing that ensure reliable performance, safety, longevity.

Our team try dedicated to supplying you with of apparatus the Ceramic tube for furnace. Each member of our team is faithfully accountable and dealing for virtually any little bit of work they do. We have been certain that our talents and efforts will bring you better work.

Our products are Ceramic tube for furnaceutilized in mining, geology metallurgy, electronics, building materials ceramics, chemical industry medical, light industry, cosmetology, environmental protection, etc.

We could be the Ceramic tube for furnace manufacturing that combines research manufacturing, sales, and service. As one of the Hi-tech major Enterprises of Torch Arrange CHISHUN was house to the best technical personnel hold a number of patents, also cooperated with local professors of NJU, NUST and HHU.

Our instruments are Ceramic tube for furnace, yet feature-rich efficient, and low in noise, which can make them often instruments perfect accumulate particulate samples (four samples in 1 test) in scientific research institutes such as universities, colleges and universities as well as in corporate research laboratories.