The field of material processing brings a fresh new approach to innovation with the exciting technological developments that are breaking down limits for what is possible. These developments have facilitated progress in many scientific disciplines. The High Energy Planetary Ball Mill is a game-changer as far as technologies are concerned. The technology quickly became a workhorse in the lab, fundamentally changing how NPs were synthesized and functionalized.

The high energy planetary ball mill is often referred to as a shaker-mill or an extremely sophisticated grinding equipment in pure form. It utilizes sound kinetic strength with hugely mechanical vitality data converters MOD Converter end result new content scale.nanise.Transaction U type local=end={()=>{nanpush()}90000}}} This opens properties that were until now out of reach by conventional ways. In this blog, we will dive into the intricacies of this approach and look at how it plays a major role in nanoparticle synthesis, have an overview about its scientific principles which drive its functionality as well as cover some diverse applications that are offered by green processing.

High energy planetary ball mills are at the heart of what nanoceramics means. High-energy mills, unlike the ball mill which only uses a certain degree of rubbing to achieve size reduction and particle-size homogeneity (and even in this case all materials must be wet ground), hightech high-strength impact type reducers can make powder grinding hard. Here, this higher energy input is used to produce particles in a size range which often spans from sub-nanometre up to hundreds of nanometers. This opens the door to potential new applications in electronics, pharmaceuticals, catalysts and energy storage systems. These mills allow scientists to manipulate material properties at a basic level by overcoming scale limitations, thereby accelerating research and development in advanced materials science.

High-energy ball mills work to counteract this common issue in design using a physics & engineering approach. All the jars are rotated around their own center so as to be able to unleash a centrifugal force mixing effect, in those gravitational devices that remain capable of continuous rotation and thus will be presented with new geometrical configurations.-The Coriolis forces generated by this rotating arrangement- This strong mixing action has several possible advantages over other means of introducing the mate- rial into and through a milling system, such as disso-lution under pressure or heat: 1. Moreover, the mill's operating conditions such as rotation speed (rpm) and ball to powder ratio can be manipulated further for tuning fabrication procedures as per material requirements. With the ability to alter these types of subtle features, this method provides a high level of control on particle properties and is highly valuable for researchers.

Although the small size reduction range indicates possibly narrower limits, high-energy mills have a wider potential than percussion- and impact-type disc attrition heads. On the other hand, they are reversible and they can modify shape and dynamical of the materials (but also new ones), as well as surface properties. An example of how they can be utilised is in the area mechanical alloying to produce metal alloys with enhanced place properties or by merely exfoliating layered materials to yield new substances such as graphene (Geimetal. Their potential of generating reactive surfaces due to mechanical activation, pave the way for innovative composites and catalysts. These mills are also specially designed to produce powders with a nanocrystalline structure and nanopores, both of which are crucial for drug delivery systems as well as energy storage devices. These attributes make high-energy ball mills an important multifunctional tool for materials scientists as shown in the figure below.

High energy planetary ball mills are marketed as a new, eco-friendly alternative that is environmentally friendly to the widespread use of traditional chemical synthesis methods. They are considered environmentally greener than the thermal processing techniques owing to decreased use of harmful solvents and energy. The closed-system operation of these mills minimises dust and exposure to the user, creating a safer work environment. On top of that, products produced with milling media are Eco-Friendly allowing for recycling and re-use. These mills stand as a big step in the right direction for industries moving to cleaner and more efficient material processing solutions.

Finally, high energy planetary ball mills are representative of the combination between technology and materials science that provide innovative approaches for nanoparticle synthesis to move forward. The unique capabilities that are based on solid scientific principals have created a paradigm shift in the field of material processing enabling an innovative approach while being environmentally sound. These mills are and will be at the front as we push forward with nanotechnological research, which you can bet on having a huge improtance in our future.

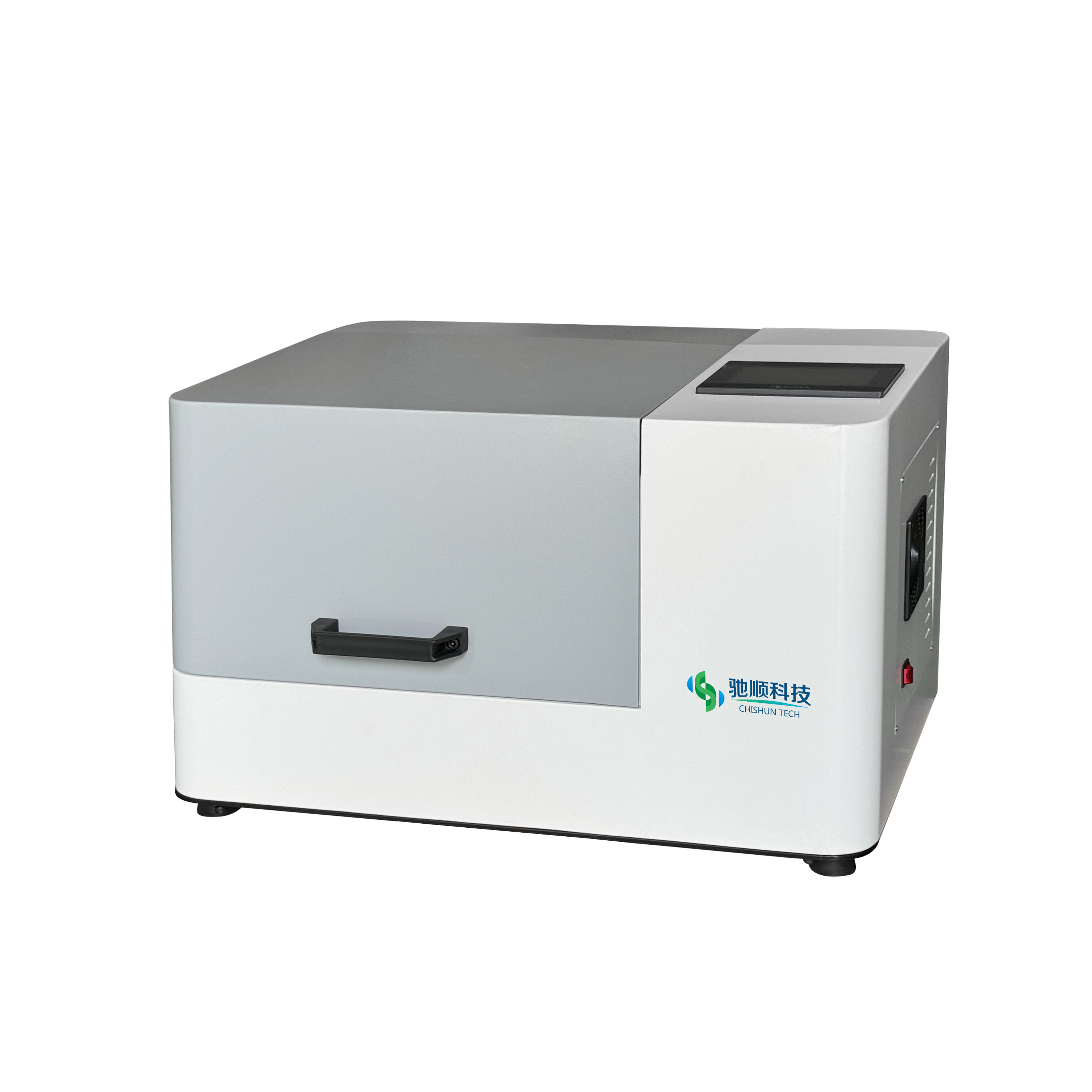

we are specialized in providing you with machines for the high energy planetary ball mill. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

Our items are high energy planetary ball mill, feature-rich, efficient, and silent. They have been perfect for obtaining particulate samples four samples for every single experiment) in scientific analysis institutes and corporate laboratories.

Our products are used high energy planetary ball millin mining, geology, electronics, metallurgy materials ceramics, chemical industry, medicine, light industry cosmetology protection environmental etc.

Our company is really a high energy planetary ball mill in manufacturing a position to combine research manufacturing, sales, and service. As one of the important Hi-tech Enterprises of Country Torch Plan, CHISHUN possessed the very best technical personnel hold many patents. along with working together with local professors from NJU, NUST and HHU.