Mechanical equipment used in scientific laboratories is the ball mill, Lab Planetary Ball Mill that has become quite popular especially developping countries. The working of this high performing machine helps us to treat various substances into the form, powder and also with other admixture combine is processed that lets us think about how intensively we give input in lessening particle size as well as in synthesizing materials. Decoding The Technical Capabilities Of A Lab Ball Mill Turning a lab planetary ball mill inside out to study its technical features and how the changes drive energy-saving solution.

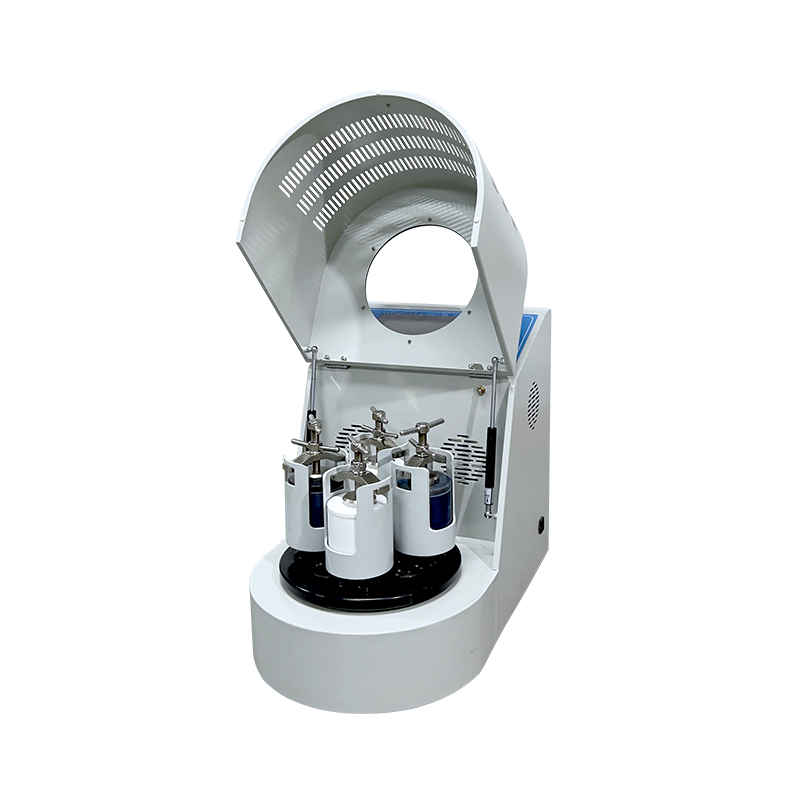

Precision Engineering at Micro and Nano Scales is a critical tool for the discovery of new materials with in laboratories as it drives innovation. In terms of grinding, there are certain materials that must be devitalized to an extent not unalike the effect achieved my conventional ball mills and for this reason it should come as a surprise less than no other lab planetary ball mill can provide such grinding solutions. The dual rotation of the jar on its own axis (planetary)and around the central SUN WHEEL is made possible using PLANETARY MOTION. To do this, both of these actions are important to create a complete and evenly sized reduction such that it can be done more quickly which is called as easy solution because instead they will actually so for advanced applications, like in ceramics or pharmaceuticals, electronics etc.

This one from across International Group(a hotbed of planetary ball mill lab experiments) I am pondering takes about 30 minutes to grind any sufficiently small material down,ou ha com), are able to reduce this size even further. The lack of collisions between balls and the material being processed lead to fracturing in important areas due to high-energy impacts, decreasing particle sizes with time. Also, the jars kept rotating in planetary mills but had been adhered to the inner wall and thus grinding media only fails impacting on jar vector (the vertical component of a particle arc trajectory) for acceleration with great centrifugal forces that z80 was strong enough work hard even after sharp impact or milling fine results. Additionally, certain adjustable processing parameters could be varied/controlled-changing the operation rotation speed of stirring rods in terms of ball sizes or powder loading for manipulation in a process condition and to modify resultant particle size. Its ability to adjust allows a versatile tool when grinding or sizing materials and extracting the perfect size fractions.

The lab planetary ball mill is as small as it gets, which means smaller particles can be used to produce finer sizes. Completely sealed from the environment, reducing sample contamination to a minimum — vital for sensitive applications like drug formulation or electronic ceramics processes. This versatility is supplemented by the dual-mode capability for dry as well as wet grinding used throughout other experimental areas. The mill is also scalable, allowing researchers to reproduce and scale up their experiments once processes are optimized at the lab level resulting in a smoother research-to-development transition. Moreover, it offers fine tuning the milling conditions to more uniformity - impacting most on reproducibility which lies in core of Scientific Integrity.

The planetary ball milling is developed towards high advancement applications. Used heat to blend elemental powders into solidified mixtures of nanoscopic grains through a process called mechanical alloying, which happens by smashing and framing followed by re-smashing and welding together tiny particles with same size. For the production of nanocrystalline or amorphous structures during solid-state reactions that normally stop at sub-micron scale, high energy ball milling is highly suitable due to its rapid and powerful size reduction mechanism within a short time. It also simplifies the process of producing composites made up from constituents with different properties, since reinforcement particles can be uniformly distributed amongst a matrix. Besides, it is also equipped with the cryogenic feature that allows processing heat sensitive materials without altering their properties.

Application of Energy-Saving Agate Lab Ball Mill Auxiliary Large Capacity with Competent Price

Since, sustainability is the need of hour nowadays so that lab planetary ball mill comes up as a very good example. They can easily achieve high power and reduced energy loads, helping to lower the electrical cost per tonne of material processed. The drones can be used instead of industrial mills, with their mills reducing production- and operational associated carbon emissions even further due to the fact that they are small-sized. The fine grinding properties allow materials to be burned almost completely and waste formation is reduced to a minimum, which are prerequisites for the use of products in closed loop recycling solutions. The planetary ball mill used in this study was a Fritsch Pulverisette 7 with stainless steel vials and balls were employed for blending andparticlesizing agues. One practical perspective is the sustainable use of planetary millenary signposts in classification.

We are a lab planetary ball millmanufacturing that integrates research, production, sales and services. Being 1 of the key Hi-tech Enterprises of Country Torch Plan CHISHUN was in fact home to an excellent group of personnel and hold many patents. in addition to dealing with local teachers of NJU, NUST and HHU.

Our goods are employed lab planetary ball millin geology, mining, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, cosmetology, environmental protection etc.

Our items are lab planetary ball mill, feature-rich, efficient, and silent. They may be perfect for capturing particles 4 samples for every experiment) in scientific research institutes and corporate laboratories.

All of us is invested in supplying both you and tools of this lab planetary ball mill. Every member of all of us is dedicated plus accountable with their perform. We have been certain that our abilities and work makes it possible to achieve greater outcomes.