- ملخص

- المعلمة

- سمات

- استفسار

- المنتجات ذات الصلة

وصف :

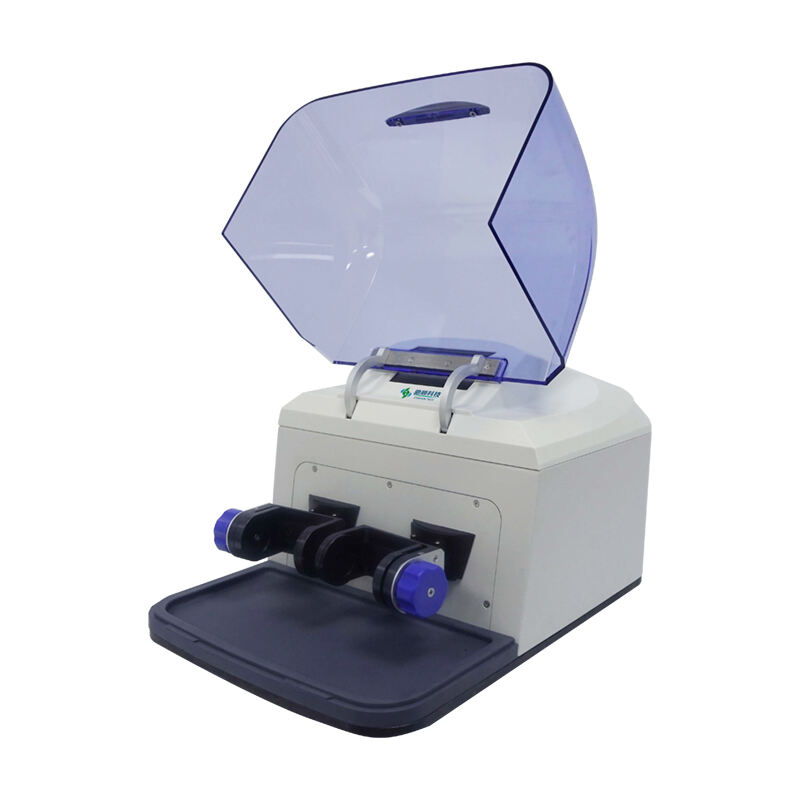

مطحنة كروية كوكبية MN04 هو جهاز ضروري لخلط، الطحن الدقيق، إعداد العينات، تشتت المواد النانوية، تطوير منتجات جديدة وإنتاج دفعات صغيرة من المواد التكنولوجية المتقدمة. يمتلك المنتج مزايا الحجم الصغير، الوظائف الكاملة، الكفاءة العالية وضوضاء منخفضة. إنه معدّ جيد للحصول على عينات بحثية تحتوي على جزيئات دقيقة للمؤسسات البحثية، الجامعات ومختبرات الشركات (يمكن الحصول على أربع عينات في نفس الوقت مع كل تجربة). يمكن طحن العينة في فراغ. يتم استخدام المنتجات بشكل واسع في الجيولوجيا، الموارد المعدنية، الميتالورجيا، الإلكترونيات، مواد البناء، السيراميك، الكيمياء، الصناعات الخفيفة، الطب، التجميل، حماية البيئة وغيرها من الأقسام.

النظام الكهربائي مطحنة كروية كوكبية MN04 يأتي مطحنة الكرات الكوكبية المكتبية مزودة بأربع خزانات طحن كروية على نفس الطاولة الدوارة. عندما تدور الطاولة، يدور خزان الطحن الكروي حول محور الطاولة الدوارة لحركة كوكبية. تقوم كرة الطحن داخل خزان مطحنة الكرات بطحن وخلط العينة أثناء الحركة السريعة. يمكن طحن المنتج بطريقة جافة أو رطبة وخلط منتجات ذات أحجام وأصناف مختلفة، ويمكن أن يصل أصغر حجم للمنتج المطحون إلى 0.1 ميكرون (أي 1.0X10mm4).

التفاصيل الفنية :

مطحنة كروية كوكبية MN04

|

مجالات التطبيق: |

مواد إلكترونية، تربة، مواد طيران، بطاريات، سيراميك، بيولوجيا، جيولوجيا ومصادر معدنية، علم المعادن. |

|

خصائص العينة: |

ناعمة، صلبة، هشة، ليفية، جافة أو رطبة. |

|

القدرة القصوى للتحميل: |

2/3 من حجم خزان الطاحونة الكروية. |

|

الطحن تحت الفراغ: |

خزان طحن اختياري تحت الفراغ. |

|

الحجم الأقصى للحقن: |

مادة التربة ≤ 10 مم، المواد الأخرى ≤ 3 مم. |

|

حجم التفريغ النهائي: |

أدنى مستوى يصل إلى 0.1 ميكرون (أي 1.0X10mm4). |

|

توقيت البديل: |

1-9999 دقيقة. |

|

سرعة طاحونة الكرات: |

دوران 500 دورة في الدقيقة، دوران 1000 دورة في الدقيقة. |

|

حجم عبوة الطحن: |

50 مل، 100 مل. |

|

مواصفات خزان الشفط: |

50 مل. |

|

شهادة الأجهزة الكهربائية: |

شهادة التحقق من UL، شهادة CE. |

|

شهادة الأمان: |

اجتازت شهادة CE الأوروبية (الرقم التسلسلي: 802693615232). |

|

تسارع الطرد المركزي: |

(g=9.81m/s2): 34g. |

|

وصف كهربائي: |

220V 0.75kw 50~60Hz. |

|

تفاصيل التغليف: |

535*425*320mm 310*260*410mm |

|

تخزين البيانات: |

يمكن تخزين عدة مجموعات من الخطوات العملية المختلفة. |

|

مراقبة البيانات: |

مراقبة في الوقت الفعلي لحالة التشغيل ودعم مراقبة الأعطال. |

|

العملية القابلة للبرمجة: |

5 مجموعات من خطوات البرمجة. |

|

ترقية البرامج: |

توفير خدمة الترقية المجانية مدى الحياة. |

|

وضع التحكم: |

واجهة بشرية رسومية باللغتين الصينية والإنجليزية (تم تثبيت نسخة برنامج التحكم في الطاحونة الكروية Chishun V1.0 بشكل افتراضي)، الوضع التشغيلي القابل للبرمجة بعدة طرق (تشغيل إيجابي وسلبي متكرر، تشغيل فاصل، تشغيل مؤقت)، وظيفة تخزين البيانات وحفظها، إعدادات البرنامج الحرة، إنذار تلقائي. |

|

مادة مجموعة الطحن: |

الفولاذ المقاوم للصدأ، الفولاذ المقاوم للصدأ شبه الفراغ، العقيق، السيراميك، الزركونيا، النيلون، البولي تيترا فلوريد، كربيد التنجستن سايغانج، نيتريد السيليكون، إلخ. |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH