- Übersicht

- Parameter

- Anfrage

- Verwandte Produkte

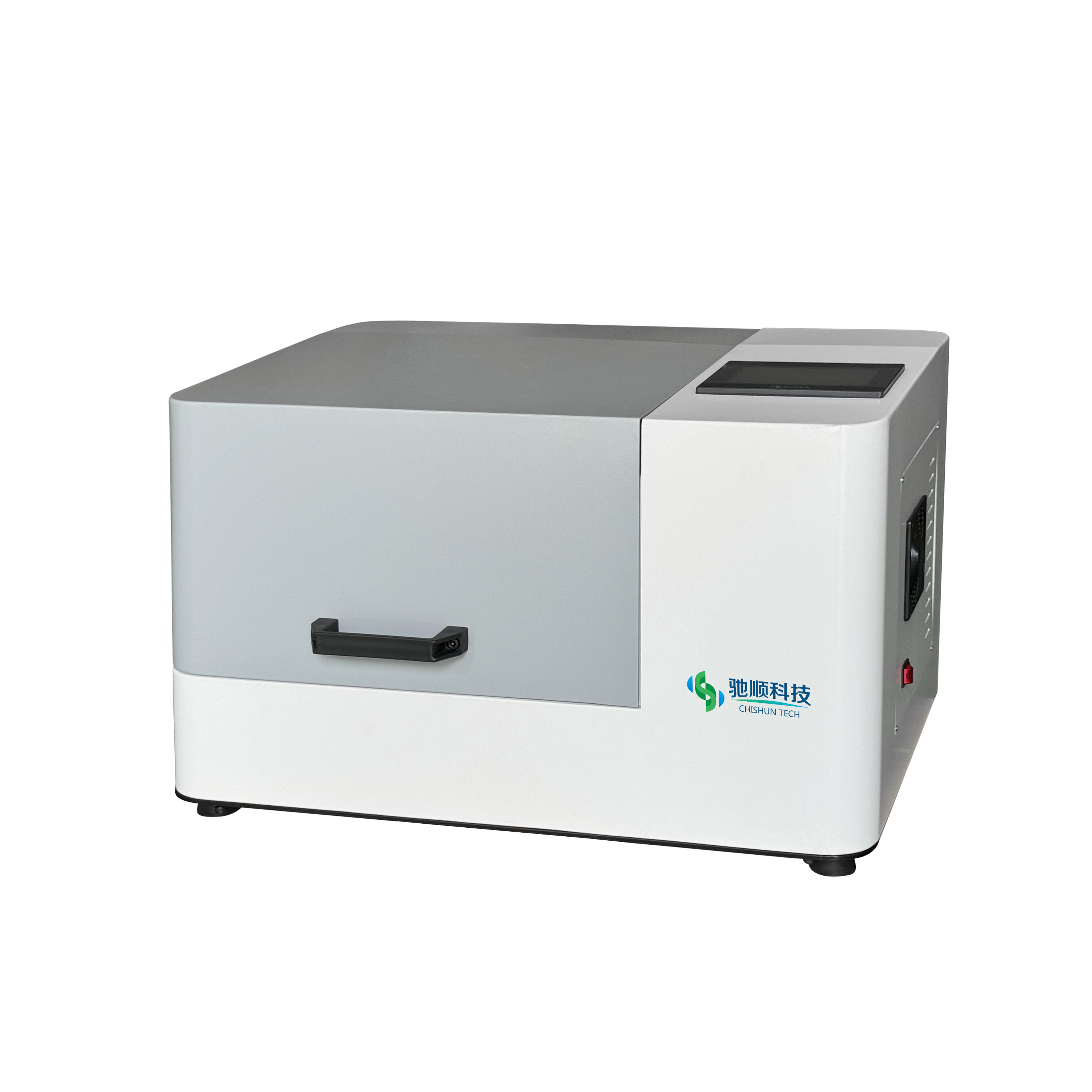

Kurze Beschreibung:

Der PULVERIZER 500 (4-Becher) Hochenergie-Planetenballmühle ist mit vier Mahlanlagen auf demselben Teller ausgestattet. Wenn der Teller rotiert, dreht sich der Ballmahlbehälter um die Achse des Tellers und gleichzeitig um seine eigene Achse, was eine planetare Bewegung erzeugt. Schleifmittel und Probenmaterial rollen bei hoher Geschwindigkeit im Mahlbehälter, wodurch starke Scherkräfte, Impacts und Rollbewegungen der Materialien entstehen, um das Ziel der Zerkleinerung, Mahlung, Dispersion und Emulgation von Materialien zu erreichen.

Der PULVERIZER 500 (4-Tassen) Hochenergie-Planetenkugelmühle ist eine ultrahochleistungsfähige Planetenbällermühle, die aus zwei Einzeltankbasen besteht, die sich auf demselben Laufwerk befinden. Die Maschine ist klein, einfach zu bedienen und erreicht Drehzahlen von bis zu 400 Umdrehungen pro Minute. Sie kann Materialien wie hartes, weiches, sprödes, trockenes und feuchtes Material kontinuierlich und effizient zerkleinern und mahlen, ohne Verluste. Gleichzeitig erfüllt die PULVERIZER 500 (4-Tassen) Hochenergie-Planetenkugelmühle auch die technischen Anforderungen und Energieeinsatz für die mechanische Legierungsbearbeitung und das Mahlen von Kolloidmaterialien.

Wie es funktioniert:

Das Zerkleinern und Mahlen von Materialien wird hauptsächlich durch Hochgeschwindigkeits-Reibung und Kollision zwischen den Mahlkugeln realisiert. Wenn die Scheibe rotiert, dreht sich der Mahlbehälter mit dem Probenmaterial und der Mahlkugel in hoher Geschwindigkeit um seine Mittelachse in entgegengesetzter Richtung. Bei einer bestimmten Geschwindigkeit trennt die Zentrifugalkraft die Probe und die Mahlkugel von der Innenwand des Mahlbehälters. Die Mahlkugel bewegt sich in hohem Tempo hin und her im Behälter, und die Probe wird weiter gemahlen, indem sie gegen die Behälterwand stößt. Darüber hinaus beschleunigt auch die Aufprallkollision zwischen den Mahlkugeln die Verringerung der Probengröße. Die Hauptplatte der Sonnenscheibe des PULVERIZER 500 Vier-Behälter Hochenergie-Planetenballmühle hat eine Drehzahl von bis zu 400 Umdrehungen pro Minute und eine Zentrifugalkraft von 22g.

Spezifikationen:

|

Maximale Futtergröße: |

10mm |

|

Behältervolumen: |

500ml*4, 250ml*4, 80ml*8 (gestapelte Tanks) |

|

Endfeinheit: |

<0,1um |

|

Inertgas-Mahlung: |

Kann im Handschuhfach erreicht werden |

|

Mahlmodus: |

Trockenmahlung、Nassmahlung |

|

Typische Mahlzeit: |

5 Minuten. |

|

Drehgeschwindigkeit der Hauptplatte: |

100-400 U/min |

|

Übertragungsverhältnis: |

1:-2.19 |

|

Durchmesser der Hauptplatte: |

420mm |

|

Sicherheitseinrichtung: |

Es gibt mehr als 4 Stück dickere Metallteile, um die Sicherheit zu gewährleisten |

|

Sicherheitseinrichtung für das Glasgefäß: |

Doppelverschlüsse, Drehverschlusseinrichtung und Druckverschlusseinrichtung |

|

Zentrifugalbeschleunigung: |

(g=9.81m/s2):22g |

|

Kühlgitter: |

Unterstützt durch optionales Kühlgerät |

|

Bescheinigung: |

UL, CE |

|

Leistung: |

AC220V 50-60Hz 1,5kw |

|

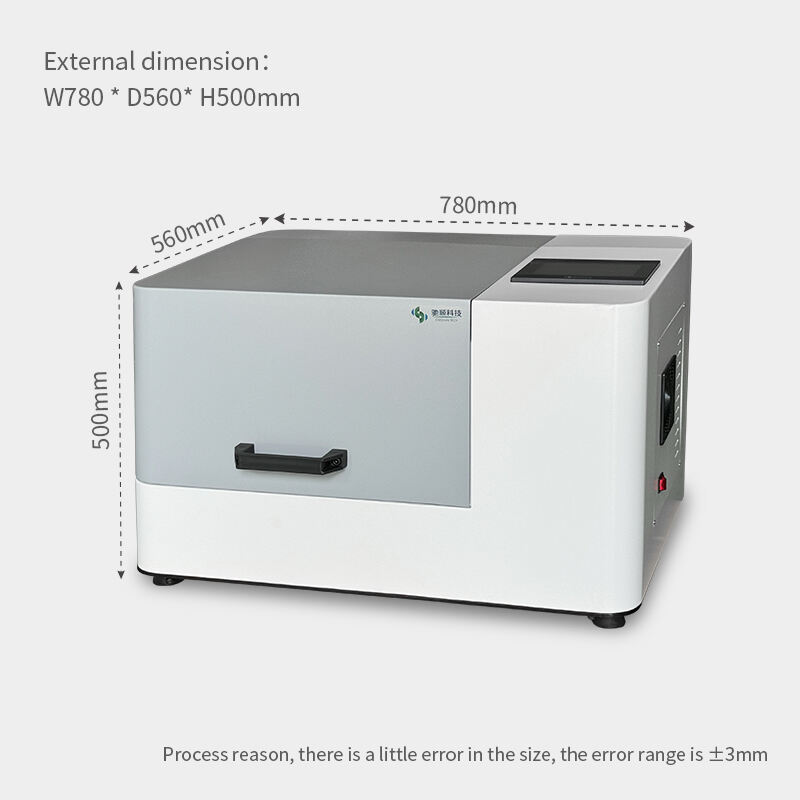

Verpackungsdetails: |

78*56*80cm >160kg |

|

Steuerungsmodus: |

7" HMI-Touchscreen, Mehrere Betriebsmodi (vorwärts- und rückwärts wechselnder Betrieb, Intervallbetrieb, zeitgesteuerten Betrieb) |

|

Abluftgerät: |

Doppelfan-Zwangsbelüftungsdesign, effektiv reduziert die Temperatur der Mahlkammer während des Kugelmahlprozesses |

|

Gefäßmaterialien: |

Edelstahl, Vakuum, Jaspis, Zirkonia, Alumina, PTFE, Nylon, Wolframkarbid usw. |

Wettbewerbsvorteil:

1) Direktlieferung vom Werk

2) Qualitätsgarantie

3) Bestpreis

4) Kompakt in der Größe

5) Vollständige Spezifikationen

6) Servicegarantie

Schlüsselparameter

Behältervolumen: 500ml*4, 250ml*4, 80ml*8

Typische Mahlzeit: 5 Minuten.

Drehgeschwindigkeit der Hauptplatte: 100-400 U/min

Übertragungsverhältnis: 1:-2.19

Durchmesser der Hauptplatte: 420mm

Zentrifugalbeschleunigung: (g=9.81m/s2):22g

Leistung: AC220V 50-60Hz 1,5kw

Verpackungsdetails: 78*56*80cm 95kg

Steuerungsmodus: 7" HMI-Touchscreen, Mehrere Betriebsmodi (vorwärts- und rückwärts wechselnder Betrieb, Intervallbetrieb, zeitgesteuerten Betrieb)

Gefäßmaterialien: Edelstahl, Vakuum, Jaspis, Zirkonia, Alumina, PTFE, Nylon, Wolframkarbid usw.

DE

DE

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH