- Overview

- Parameter

- Features

- Inquiry

- Related Products

Description:

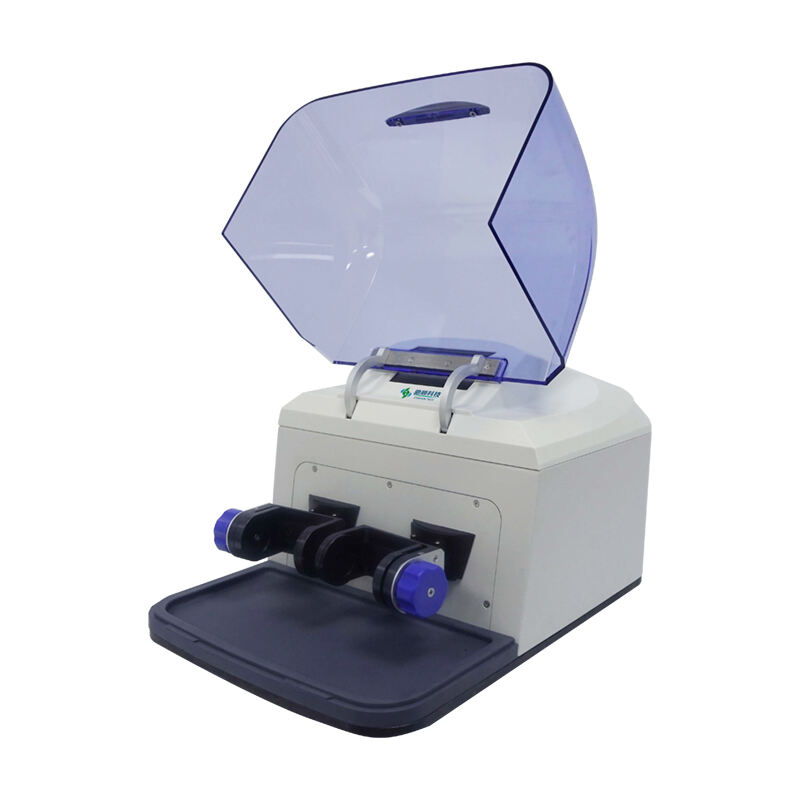

QM-WX2horizontal planetary ball mill is a new device for mixing, fine grinding, sample preparation, new product development and small batch production of high-tech materials. The product has the advantages of small size, full function, high efficiency and low noise. it is an ideal equipment for scientific research institutions, colleges and universities and enterprise laboratories to obtain research samples (four samples can be obtained at the same time in each experiment). The QM-WX2horizontal planetary ball mill is equipped with vacuum ball mill, which can grind the sample in vacuum. Widely used in geology, mineral resources, metallurgy, electronics, building materials, ceramics, chemical, light industry, medicine, environmental protection and other departments.

The QM-WX2horizontal planetary ball mill is symmetrically equipped with four horizontal installed ball mill tanks on a vertical plane turntable. When the turntable rotates (rotates), the ball mill tank rotates (rotates) around its own central axis. Because there is no fixed bottom surface of the ball grinding tank when rotating, in the process of grinding materials, the grinding ball in the tank is not only affected by the centrifugal force of rotation and rotation, but also plays a certain role. The magnitude and direction of the resultant force acting on each grinding ball are constantly changing and different, which makes the trajectory of all grinding balls disorganized. When the machine is running at high speed, the grinding ball obtains enough collision energy and violently hits and grinds the material, which greatly improves the grinding effect and grinding efficiency.

Specifications:

QM-WX2

Application areas: |

Electronic materials, soil, aviation materials, batteries, ceramics, biology, geology and mineral resources, metallurgy. |

Sample characteristics: |

Soft, hard, brittle, fibrous, dry or wet. |

Maximum loading capacity: |

2/3 of the volume of the ball mill tank. |

Vacuum grinding: |

Optional vacuum grinding tank. |

Working method: |

horizontal grinding |

Maximum injection size: |

Soil material ≤ 10mm other materials ≤ 3mm. |

Final discharge granularity: |

Minimum up to 0.1um (that is, 1.0X10mm4). |

Alternate timing time: |

1-9999min. |

Ball mill speed: |

Rotation 325rpm/min, rotation 650rpm/min. |

Grinding can size: |

250ml 、 500ml. |

Packaging Details: |

665*480*500mm |

Electrical appliance certification: |

UL certification, CE certification. |

Security Certification: |

Passed EU CE Certification (S/N:802693615232). |

Centrifugal acceleration: |

(g=9.81m/s2): 20g. |

Electrical description: |

220V 0.75kw 50~60Hz. |

Data storage: |

Can store multiple sets of different process steps. |

Data monitoring: |

Real-time monitoring of running status and support for fault monitoring. |

Programmable operation: |

5 groups of programming steps. |

Software upgrade: |

Provide free upgrade service for life. |

|

Control mode: |

Chinese and English interchange graphical man-machine interface (pre-installed Chishun ball mill control software version V1.0), programmable multiple operation modes (positive and negative alternating operation, interval operation, timing operation), data storage and memory function, free program setting, automatic alarm. |

Grinding kit material: |

Stainless steel, vacuum stainless steel, agate, ceramics, zirconia, nylon, polytetrafluoro, tungsten carbide,Saigang, Silicon Nitride, etc. |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH