- Обзор

- Параметры

- Особенности

- Запрос

- Связанные продукты

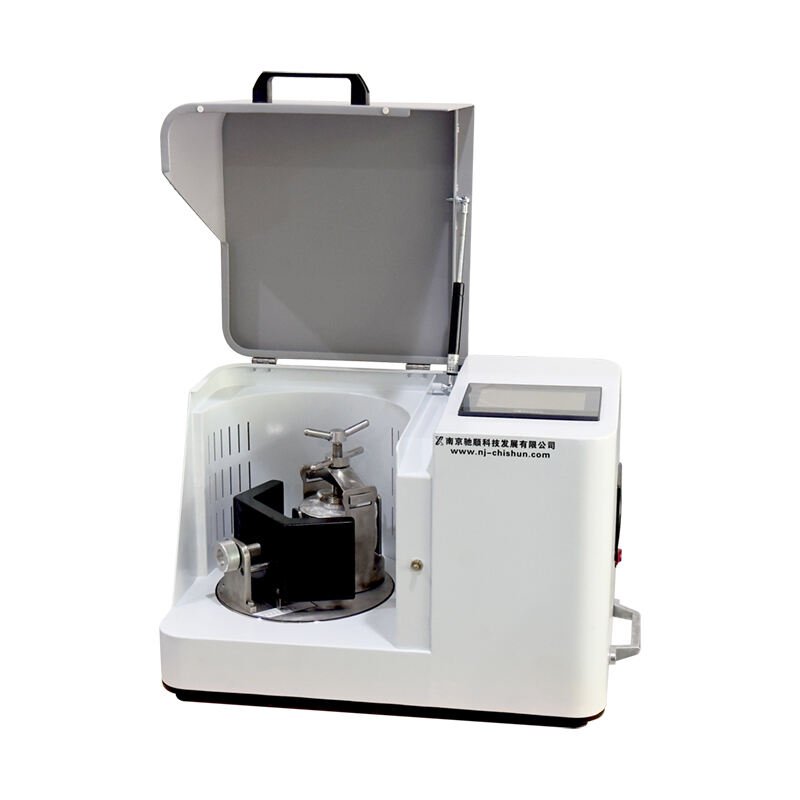

Описание:

Низкотемпературная планетарная шаровая мельница представляет собой комбинацию планетарной шаровой мельницы и криогенного охлаждающего оборудования. Большинство материалов нагревается из-за трения или экзотермической реакции в процессе высокоскоростного измельчения, что может привести к изменениям физических и химических свойств материалов и вызвать негативный эффект измельчения. Низкотемпературная планетарная шаровая мельница主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于主要用于в основном применяется в процессе измельчения материалов, для которых необходимо строго контролировать температуру.

принцип работы :

Планетарная мельница с низкой температурой постоянно подает холодный воздух, производимый системой воздушного охлаждения, в планетарную мельницу с изоляционной крышкой. Эти кондиционеры поглощают и удаляют тепло, выделяемое высокоскоростным вращающимся бункером мельницы вовремя, чтобы бункер мельницы с материалами и шариками для измельчения всегда находился в определенной низкотемпературной среде. Низкотемпературная планетарная мельница расширяет область применения того же материала благодаря реализации низкотемпературного измельчения, а также расширяет применение материалов, что позволяет измельчать некоторые материалы, которые раньше нельзя было обрабатывать (качественные изменения, вызванные повышением температуры, деформация).

Спецификации:

Применение: |

Электронные материалы, почвы, космические материалы, батареи, керамика, минералы, металлургия и т.д. |

Применяемые образцы: |

Мягкие, твердые, хрупкие, волокнистые, сухие или влажные |

Макс. объем подачи: |

2/3 от объема измельчающей емкости |

Измельчение в вакууме: |

дополнительно |

Размер подачи: |

почва≤10мм, другие≤3мм |

Конечная тонкость: |

0.1μm |

Альтернативное время: |

1-9999мин |

Вращение |

580об/мин |

Температура охлаждения: |

-40℃~20℃ |

Метод охлаждения: |

Охлаждение жидким азотом или воздушное охлаждение |

Расход газа (0~-10℃) |

2-5 Л/ч |

Измельчающая камера: |

250мл, 500мл |

Вакуумная камера: |

250 мл |

Сертификат: |

UL, CE |

Мощность: |

220В 0.75квт 50~60Гц |

Подробности упаковки: |

88*59*90см 220КГ |

Хранение данных: |

120 наборов процессов |

Мониторинг данных: |

Мониторинг операционного состояния в реальном времени, поддержка тревожных сигналов при неисправностях |

Программируемая операция: |

6 наборов операционных шагов с поддержкой редактирования/удаления |

Режим управления: |

7" ГМИ сенсорный экран, М несколько режимов работы (переменная прямая и обратная работа, интервальный режим, таймер) |

Материалы банок: |

Нержавеющая сталь, вакуум, агат, цирконий, оксид алюминия, ПТФЭ, нейлон, вольфрамокарбид и др. |

Конкурентное преимущество:

1) Прямая доставка с завода

2) Гарантия качества

3) Лучшая цена

4) Компактный размер

5) Полная спецификация

6) Гарантия обслуживания

Основные параметры:

Применяемые образцы:

Мягкие, твердые, хрупкие, волокнистые, сухие или влажные

Размер подачи:

почва≤10мм, другие≤3мм

Конечная тонкость:

0.1μm

Температура охлаждения:

-40℃~20℃

Вращение:

580об/мин

Режим управления:

7" сенсорный экран HMI, Несколько режимов работы (переменная прямая и обратная работа, интервальный режим, таймерный режим)

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH