- ภาพรวม

- พารามิเตอร์

- คุณสมบัติ

- สอบถาม

- ผลิตภัณฑ์ที่เกี่ยวข้อง

คำอธิบาย:

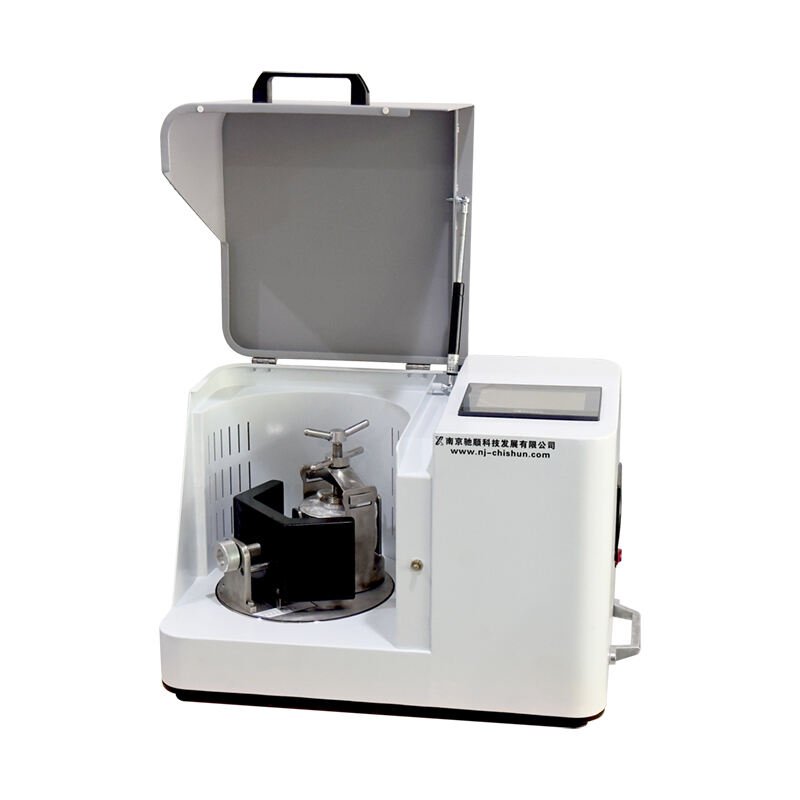

เครื่องโม่ลูกกลิ้งแบบดาวเคราะห์ที่อุณหภูมิต่ำเป็นการรวมกันของเครื่องโม่ลูกกลิ้งแบบดาวเคราะห์และอุปกรณ์ทำความเย็นแบบไครโอเจนิก วัสดุส่วนใหญ่จะเพิ่มขึ้นเนื่องจากแรงเสียดทานหรือปฏิกิริยาออกซิเดชันในกระบวนการบดความเร็วสูง ซึ่งอาจทำให้เกิดการเปลี่ยนแปลงในคุณสมบัติทางกายภาพและเคมีของวัสดุและสร้างผลลัพธ์การบดเชิงลบ เครื่องโม่ลูกกลิ้งแบบดาวเคราะห์ที่อุณหภูมิต่ำใช้หลักในการบดวัสดุที่ต้องควบคุมอุณหภูมิอย่างเข้มงวด

หลักการทำงาน :

เครื่องบดลูกกลิ้งแบบดาวเคราะห์ที่อุณหภูมิต่ำจะป้อนอากาศเย็นที่ผลิตโดยระบบทำความเย็นด้วยอากาศเข้าสู่เครื่องบดลูกกลิ้งแบบดาวเคราะห์ที่มีฝาครอบฉนวนอย่างต่อเนื่อง และเครื่องปรับอากาศเหล่านี้จะดูดซับและนำความร้อนที่เกิดจากถังลูกกลิ้งหมุนเร็วออกไปทันที ทำให้ถังลูกกลิ้งที่บรรจุวัสดุและลูกบดอยู่ในสภาพแวดล้อมที่อุณหภูมิต่ำเสมอ การบดลูกกลิ้งแบบอุณหภูมิต่ำขยายขอบเขตการใช้งานของวัสดุเดียวกันเนื่องจากการทำให้เกิดการบดที่อุณหภูมิต่ำ และยังขยายขอบเขตการใช้งานของวัสดุใหม่ๆ เนื่องจากการทำให้เกิดการบดที่อุณหภูมิต่ำ ทำให้วัสดุบางชนิดที่ไม่สามารถบดได้ก่อนหน้านี้ (การเปลี่ยนแปลงคุณภาพที่เกิดจากอุณหภูมิเพิ่มขึ้น การเสียรูป) สามารถบดได้

ข้อมูลจำเพาะ:

การใช้งาน: |

วัสดุอิเล็กทรอนิกส์ ดิน เครื่องบินและอวกาศ แบตเตอรี่ เซรามิก แร่โลหะurgy เป็นต้น |

ตัวอย่างที่ใช้ได้: |

นุ่ม แข็ง แตกหักง่าย เป็นเส้นใย แห้งหรือเปียก |

ปริมาณป้อนสูงสุด: |

2/3 ของถังบด |

การบดในสุญญากาศ: |

ตัวเลือก |

ขนาดป้อน: |

ดิน≤10mm อื่นๆ≤3mm |

ความละเอียดปลาย: |

0.1μm |

การจับเวลาแบบอื่น: |

1-9999 นาที |

การหมุน |

580rpm |

อุณหภูมิการทำความเย็น: |

-40℃~20℃ |

วิธีการทำให้เย็น: |

การระบายความร้อนด้วยไนโตรเจนเหลวหรือการระบายความร้อนด้วยอากาศ |

การบริโภคก๊าซ (0~-10℃) |

2-5 ลิตร/ชั่วโมง |

กระบอกบด: |

250ml, 500ml |

กระบอกสุญญากาศ: |

250 มิลลิลิตร |

ใบรับรอง: |

UL, CE |

พลังงาน: |

220V 0.75kw 50~60Hz |

รายละเอียดบรรจุภัณฑ์: |

88*59*90cm 220KG |

การจัดเก็บข้อมูล: |

กระบวนการ 120 ชุด |

การตรวจสอบข้อมูล: |

การตรวจสอบสถานะการทำงานแบบเรียลไทม์ รองรับการแจ้งเตือนข้อผิดพลาด |

การดำเนินการแบบโปรแกรมได้: |

ขั้นตอนการดำเนินงาน 6 ชุด รองรับการแก้ไข/ลบ |

โหมดควบคุม: |

หน้าจอ HMI ขนาด 7" สัมผัสหน้าจอ, ม ultiple โหมดการทำงาน (การปฏิบัติงานสลับไปกลับ, การทำงานเป็นช่วงๆ, การทำงานตามเวลาที่กำหนด) |

วัสดุกระป๋อง: |

สแตนเลส, วакคูม, อเกต, ซิร์โคนิเอ, อะลูมินา, PTFE, ไนลอน, ทังสเตนคาร์ไบด์, ฯลฯ |

Competitive Advantage:

1) ส่งตรงจากโรงงาน

2) การรับประกันคุณภาพ

3) ราคาดีที่สุด

4) ขนาดกะทัดรัด

5) ข้อมูลจำเพาะครบถ้วน

6) การรับประกันบริการ

พารามิเตอร์หลัก:

ตัวอย่างที่ใช้ได้:

นุ่ม แข็ง แตกหักง่าย เป็นเส้นใย แห้งหรือเปียก

ขนาดป้อน:

ดิน≤10mm อื่นๆ≤3mm

ความละเอียดปลาย:

0.1μm

อุณหภูมิการทำความเย็น:

-40℃~20℃

การหมุน:

580rpm

โหมดควบคุม:

หน้าจอสัมผัส HMI ขนาด 7", หลายโหมดการทำงาน (การทำงานสลับไปมา, การทำงานช่วงเวลา, การทำงานตามเวลา)

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH