A Revolutionary Innovation for Safe and Efficient Material Processing

If you have ever been curious about how materials are processed to create the products we use every day, you might have heard about something called high energy ball milling, also the Nanjing Chishun's product such as grinding mortar. This technology changing the way materials are ground and mixed together, and it has become a key part of many industries. We will explore what high energy ball milling, it is advantages, how to use it, and safety considerations. We will also look at some of the applications for this innovative technology, and the quality service you can expect.

High energy ball milling a process grinds materials down to a fine powder using very high speeds and energy. The Advantages of this technology include:

- Increased Efficiency: High energy ball milling typically produces finer, more uniform particles with less contamination or unwanted side reactions.

- Faster Processing: Compared to traditional milling methods, high energy ball milling processes materials in a fraction of the time, which can lead to increased productivity.

- Ability to Work with a Range of Materials: High energy ball milling can process a wide range of materials, including metals, ceramics, and polymers, making it a versatile technology, the same as lab ball mill by Nanjing Chishun.

- Greater Control: By manipulating the speed and energy of the milling, high energy ball milling allows for greater control over the final product's properties.

High energy ball milling an innovative technology has transformed materials processing, similar to the Nanjing Chishun's product like high temperature muffle furnace. Traditional methods of milling materials, such attrition or vibratory milling, require a lot of time and energy to achieve the desired results. With high energy ball milling, these same results can be achieved in a fraction of the time, making it an invaluable technology for modern manufacturing processes.

Like any technology, high energy ball milling has safety considerations must be taken into account to ensure it used safely and effectively. One of the main safety concerns the potential for explosions. This can occur if the milling process generates gases are not properly vented, or if the materials being milled are not properly handled.

- Ensure the milling chamber properly vented to prevent the buildup of gases.

- Always use protective gear when handling the milling chamber or materials, also the vibrating ball mill created by Nanjing Chishun.

- Follow all handling and storage protocols for the materials being milled.

- Identify the materials you need to process: High energy ball milling can work with a wide range of materials, so determine what you need to process and ensure it compatible with the technology.

- Choose the right milling equipment: There are different types of milling equipment can be used for high energy ball milling, the same as Nanjing Chishun's mini induction furnace. Selecting the right equipment for your needs crucial to achieving the desired results.

- Set up the milling process: This will involve properly configuring the milling equipment, including the milling chamber, milling speed, and other parameters will impact the final product.

- Monitor the milling process: It is important to monitor the milling process to ensure it working properly and the desired results are being achieved. This may involve taking samples of the material and testing them periodically.

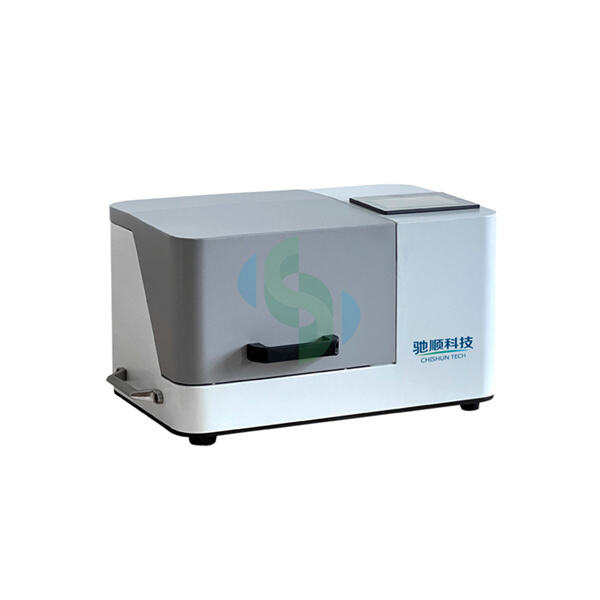

Our team is specialized in supplying you with of machines the high energy ball milling. Each member of our team does their utmost and is accountable for all work. We really hope which our skills and efforts can lead to greater results for you personally.

Our items are high energy ball milling and also the complete great deal of features, are efficient, and quiet. These are generally perfect to get particulate samples 4 samples for every single experiment) at research institutes for scientific research also since corporate labs.

Our goods are employed high energy ball millingin geology, mining, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, cosmetology, environmental protection etc.

We are a high energy ball millingmanufacturing that integrates studies production, sales, plus service. CHISHUN is one of the Hi-Tech significant Enterprises of Torch Plan, had a reputable bunch of, held an amount of patents, along with worked with local faculty members at NJU, NUST, and HHU.