- Overview

- Parameter

- Features

- Inquiry

- Related Products

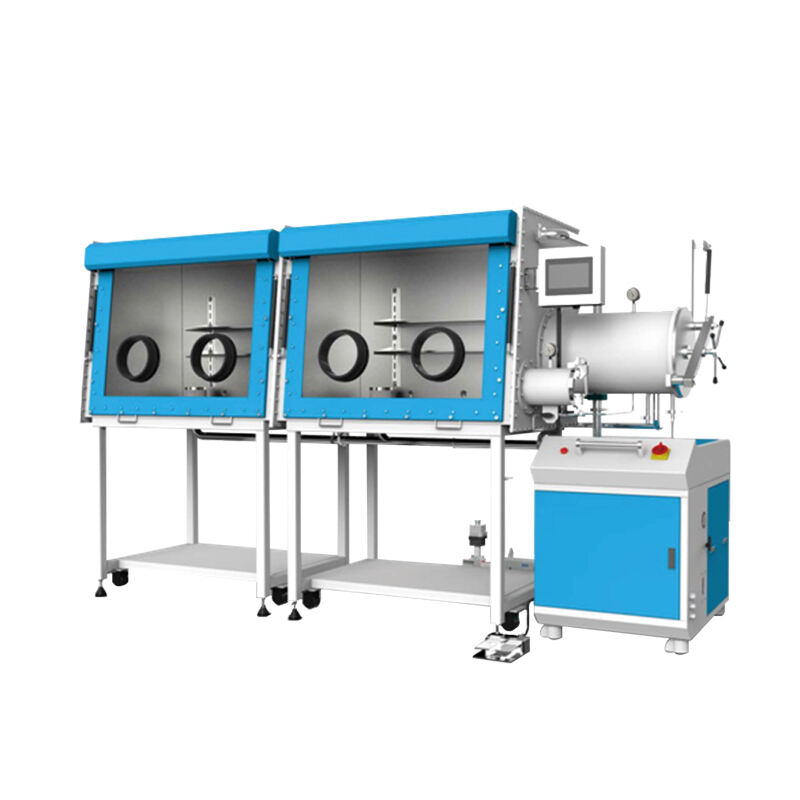

Description:

In experiments of chemical reactions and sample treatments, some substances are so sensitive to water and oxygen that they can’t be processed in atmospheric environment. Therefore, circular purification box are invented to enable the sensitive substances to react in inert gas environment without water and oxygen. The box is widely used in lithium ion batteries and materials, semiconductors, film preparation, nano materials, catalysts, super capacitors, special lamps, laser welding, brazing, titanium alloy welding, etc.

Different names:

①Cleaning cycle regeneration purification system

②Vacuum glove box

③Super purification glove box

④Automatic cleaning glove box

Competitive Advantage:

1)Factory direct delivery

2)Quality assurance

3)Best price

4)Compact in size

5)Complete specifications

6)Service Assurance

Specifications:

| 1.GLOVE BOX | |

| Dimension: | 2440*780*900mm |

| Material: | SUS 304, thickness 3mm |

| Glove opening: | φ220mm,Hard aluminum alloy material, after anti-corrosion treatment |

| Gloves: | PIERCAN made in USA; Gloves with a diameter of 8 inches and a thickness of 0.4mm are made of butyl rubber material |

| Window: |

① The inclined design of the operating surface is made of 10mm safety tempered glass, and the front window is pasted with a special customized ultra strong sealing ring, adopting a front door opening structure ② Can maintain a certain positive and negative pressure (-12mbar to 12mbar) during use ③ The box is equipped with energy-saving lighting and anti reflective materials, which provide soft light and prevent visual fatigue ④ One porous power supply terminal board is pre installed inside the box (power supply: 220V ± 10% 50Hz ± 10%) ⑤ Set up 5 standard KF-40 interfaces on the back panel of the box for easy access to liquids, gases, signals, etc ⑥ There are two layers of storage boards inside the box, which have the function of adjusting the height up and down |

| Support | Including casters, with a height of 914mm. Castors have functions such as leveling, moving, and fixing |

| Leakage rate: | Hourly leakage rate of sealed box with controlled inert atmosphere ≤ 5XMaximum leakage standard ≤ 0.05vol%/h |

| 2. Transition chamber | |

| 1)Main chamber | |

| Appearance: | Cylindrical (304 stainless steel), connected to the glove box, using manual and automatic air supply control |

| Dimension: | φ360mm*600mmRight side operation, using gas spring door opening method, with sliding tray inside the transition compartment |

| Tray: | 230 mm*595mm Can freely move left and right, with an extension depth of 361mm |

| Vacuum degree: | ≤-0.1MPa Vacuum pressure gaugeWika made in GERMAN |

| 2)Small chamber | |

| Appearance: | Cylindrical (304 stainless steel), connected to glove box, controlled by manual valve |

| Dimension: | φ155mm*320mm,Single opening handle pressing |

| Vacuum degree: | ≤-0.1MPa |

| 3.Controling system | |

| Method: | Including self diagnosis, power-off and self start characteristics, with pressure control and adaptive functions.Automatic control, cycle control, password protection, and vacuum chamber control are displayed on LCD.The control unit adopts a German SIEMENS touch screen, and the operation menu can be selected in Chinese/English |

| Pressure control: | Control the pressure of the box and transition chamber at a certain set value |

| Foot pedal: | Can control the pressure of the glove box and facilitate operation |

| 4. Purification system | |

| Purification ability: | O2、H2O < 1ppm |

| Adjustment device: | Touch adjustment through PLC (heating, evacuation, purification, regeneration)No need for human monitoring throughout the entire process |

| Working gas: | N2 or Ar(Gas circulation) |

| Circulating fan: | German Elektror imported high-speed variable frequency fan, flow rate 0-80m3/hMicroprocessor controlPressure tested stainless steel device |

| Single purification column: | 5KG German BASF deoxygenation material, capable of deoxygenation of 60L5KG American UOP high-efficiency absorbent material, capable of removing 2kg of water |

| Purification valve: | Fully automatic electrically operated valve with modular design |

| Filter: | High efficiency filter using a 0.3 micron aperture filter screen that complies with HEPA standards |

| 5. Regeneration system | |

| Used for the reuse of purification systems to activate them;Regeneration requires a mixture of N2/H2 or Ar/H2 gases, with H2 accounting for 5-10% | |

| 6. Display System | |

| The control unit adopts a German SIEMENS touch screen, and the operation menu is in Chinese/English | |

| 7.Vacuum system | |

| Automatic pneumatic electroplating boardThe vacuum pump adopts Edwards RV12 vacuum pump from the UK.Vacuum can be applied separately to the box and transition chamber, and individual control can be achieved at any time (customized project). | |

| 8. Water/oxygen analyzer | |

| Water analyzer | |

| Range: | 0-1000ppm |

| Error range: | ±1% ppm |

| Ambient temperature: | -10℃-50℃ |

| Display: | PLC |

| Especially for lithium battery manufacturing and metal organic users, it can be cleaned and reused, avoiding the problem of one-time pollution and scrapping | |

| Oxygen analyzer | |

| Range: | 0-1000ppm |

| Error range: | ±1% ppm |

| Ambient temperature: | -10℃-50℃ |

| Display: | PLC |

| The use of ZrO2 sensors avoids the problem of short lifespan and inability to be exposed to air in fuel cells | |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH