- Overview

- Features

- Inquiry

- Related Products

Brief description:

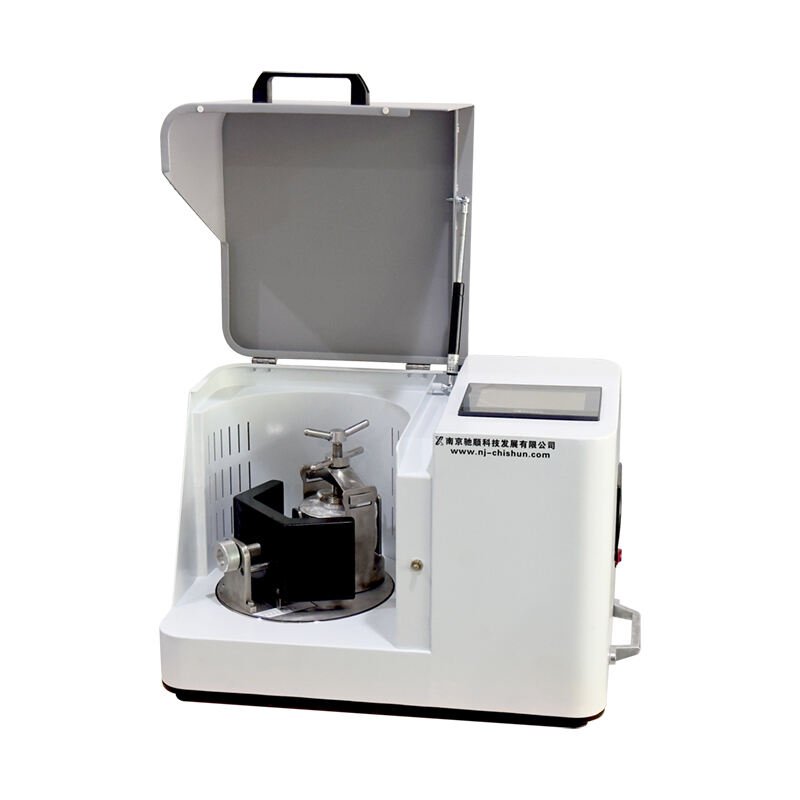

The PULVERIZER 500 single tank high energy planetary ball mill is equipped with a grinding platform and a counterweight on the same turntable. When the turntable rotates, the ball milling tank rotates around the axis of the turntable and rotates around its own axis, making planetary motion. Abrasives and test materials are used to roll at a high speed in the grinding tank to produce strong shear, impact and rolling of materials to achieve the purpose of crushing, grinding, dispersing and emulsifying materials.

How it works:

The crushing and grinding of materials are mainly realized by high-speed friction and collision between grinding balls. When the plate rotates, the grinding tank with sample material and grinding ball rotates at a high speed around its central axis in the opposite direction. At a certain speed, the centrifugal force separates the sample and the grinding ball from the inner wall of the grinding tank. The grinding ball shuttles back and forth at high speed in the tank, and the sample is further ground by hitting the tank wall. In addition, the impact collision between grinding balls also accelerates the consumption of sample size. The main disk of the solar wheel of the PULVERIZER 500 single-tank high-energy planetary ball mill has a rotating speed of up to 650rpm and a centrifugal force of 29g.

Specifications:

|

Max. feed size: |

10mm |

|

Jar volume: |

500ml*1, 250ml*1, 80ml*2(superimposed) |

|

Final fineness: |

<0.1um |

|

Inert gas grinding: |

It can be achieved in the glove box |

|

Grinding mode: |

Dry grinding、Wet griding |

|

Typical griding time: |

5min |

|

Main disc speed: |

100-650rpm |

|

Jar speed |

1183rpm |

|

Transmission ratio: |

1:-1.82 |

|

Main disc diameter: |

290mm |

|

Safety device: |

There’re more than 4 pieces of thicker metal devices to ensure safety |

|

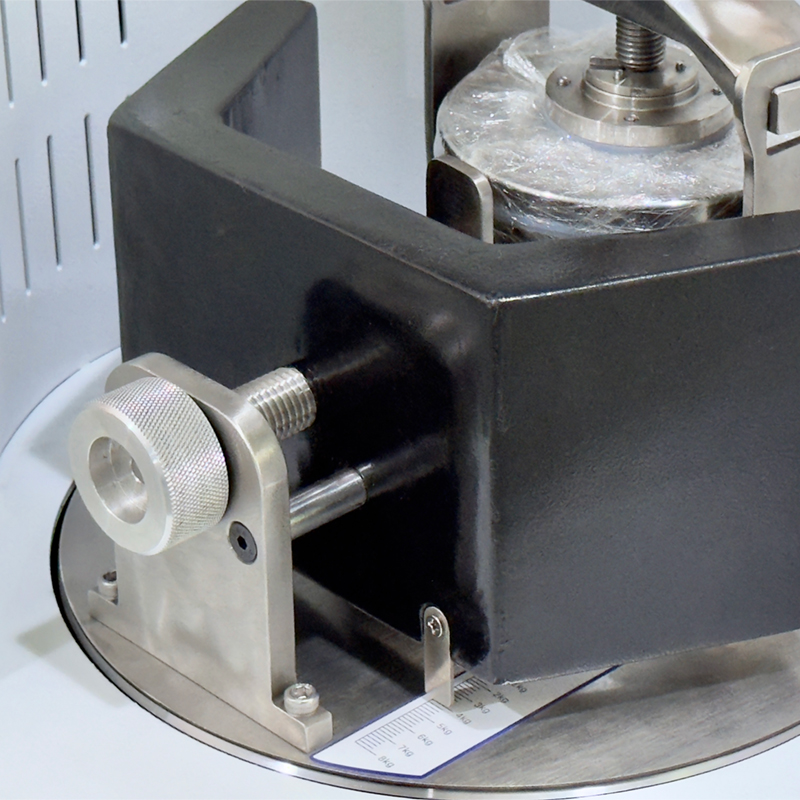

Jar safety device: |

Double locks, rotary locking device and press locking device |

|

Centrifugal acceleration: |

(g=9.81m/s2):29g |

|

Cooling griding: |

Supported upon optional cooling device |

|

Certificate: |

UL、CE |

|

Power: |

AC220V 50-60Hz 0.75kw |

|

Packaging Details: |

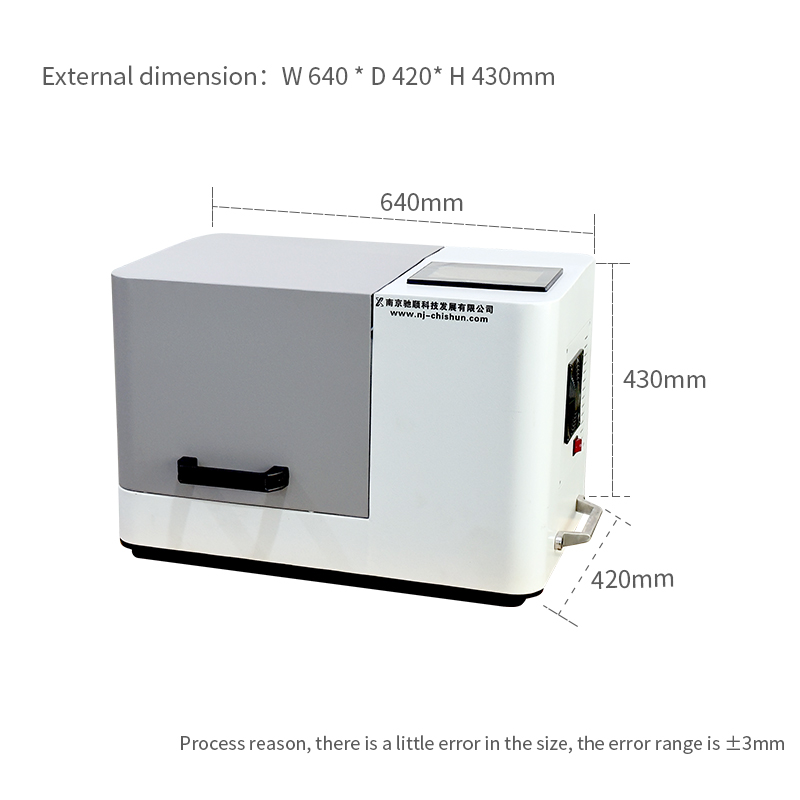

79*52*62cm 95kg |

|

Control mode: |

7" HMI touch screen, Multiple operation modes (forward and reverse alternating operation, interval operation, timed operation) |

|

Exhaust device: |

Double fan forced ventilation design, effectively reducing the temperature of the grinding chamber during ball milling process |

|

Jar materials: |

Stainless steel, vacuum, agate, zirconia, alumina, PTFE, nylon, tungsten carbide,etc. |

|

Grinding balls: |

1mm、3mm、5mm、6mm、8mm、10mm、15mm |

Competitive Advantage:

1) Factory direct delivery

2) Quality assurance

3) Best price

4) Compact in size

5) Complete specifications

6) Service Assurance

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH