- Prezentare generală

- Parametru

- Caracteristici

- Cerere de informații

- Produse conexe

Descriere:

Prezentare detaliată

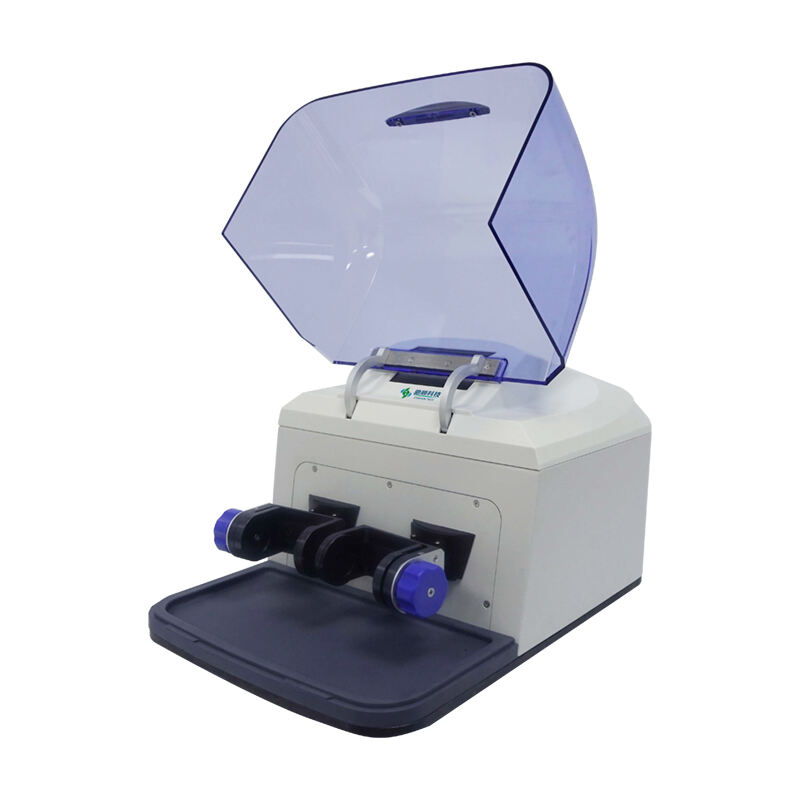

MAX-mill Mixer de performanță ridicată criogenic este un amestecator vibrațional cu energie mare și multifuncțional pe masă. MAX-mill poate amesteca și omogeniza prafuri sau suspensii până la 2100 rpm într-un timp scurt, cu viteză rapidă și operație ușoară, generând suficientă energie pentru a măcina particulele până la nivelul nanometru; Când se folosește o clădire metalică, aceasta poate fi răcită manual în azot lichid pentru a minimiza efectul încălzirii. Mixerul de performanță ridicată MAX-mill are o putere de înaltă performanță și este potrivit pentru procese de măcinare pe termen lung, făcându-l extrem de atractiv pentru cercetarea științifică și mecanochimie. Produsul este utilizat în mod larg în diferite domenii de pretratare experimentală, cum ar fi sinteza mecanochimică, biologia, chimia, farmacologia, minerale, medicina etc.

Funcție și principiu

Cutia de moară a măcinării MAX high-energy frozen mixing ball mill efectuează o oscilație radială într-o poziție orizontală, iar inerția bilor de moară determină acestea să impinguze materialul de probă la capătul rotund al cutiei de moară cu o energie ridicată și să-l dizolve. De asemenea, mișcarea cutiei de moară se combină cu mișcarea bilei, rezultând o amestecare puternică a probei. Folosind mai multe bile de dimensiuni mai mici, gradul de amestecare poate fi îmbunătățit, iar efectul mare de impact prin frecare între bilele de moară asigură fragmentarea eficientă a celulelor.

Caracteristici ale produsului

Motor îmbunătățit, șarpe importate, reglare fără trepte a vitezii;

Control printr-un ecran tactil, stocare program personalizat, protecție la deschiderea acoperișului;

Măcinare eficientă, fără necesitate de întreținere și funcționare fluidă;

Acoperiș transparent din față, protecție împotriva scurgerii și izolare a poluărilor;

Se pot înlocui diferite adaptoare, iar diverse adaptoare sunt disponibile pentru selecție;

Performanță și Design

Atinge efecte puternice de măcinare, dizolvare și homogenizare prin impact și frecare la 2100rpm;

Echipat cu 2 stații de măcinare, capabil să măcine până la 20 de probe simultan;

Un proces operațional care poate stoca mai multe segmente ale programelor;

Ecranul tactil este ușor de operat, simplu și confortabil;

Versatilitate fără egal

Trei moduri de măcinare: măcinare uscată, măcinare umedă și măcinare congelată;

Înainte de granulație, amestecați eșantionul de praf și adhesiv într-un recipient (cum ar fi analiza XRF);

Potrivită pentru cercetarea aplicată, cum ar fi mecanochimia sau fragmentarea tecahurilor celulare biologice;

Extracția componentelor pesticidale și herbale;

Aplicații biologice și soluții pentru fragmentarea celulelor

Măcinatoare mixte cu biluri la ghețar sunt adesea utilizate pentru a homogeniza probe biologice, iar măcinarea cu măcinatoare cu biluri este o metodă consolidată pentru fragmentarea celulară a levurilor, microalgelelor sau probelor bacteriene. În timpul acestui proces, proba se va încălzi doar moderat, iar efectul de încălzire poate fi minimizat prin răcire prealabilă. Măcinatoarea hibridă cu biluri de înaltă energie MAX100 poate măcina eficient până la 96 * 2ml de suspensii celulare pentru a extrage ADN/ARN și proteine. Pentru a diagnostica cu precizie o infecție, bacteriile complete pot fi izolate din tecile unui tub de probă de 10 * 5ml folosind un adaptator.

Aplicarea Sintezei Mecanochimice

Metodele mecanochimice pot permite reacții rapide ale substanțelor în medii fără solvent. Unele reacții chimice necesită fricțiunea din moarile cu bile planetare, în timp ce alte tipuri de reacții necesită introducerea energiei prin impact. Acesta este locul în care funcționează moara MAX cu energie ridicată, moara mixtă cu bile înghețate. Mărimea esenței disponibilă pentru aplicații de cercetare este de obicei foarte mică, ceea ce face ca vasele mici de macerat, cum ar fi moara MAX cu un volum de mai puțin de 50 mililitri, să fie avantajoase. Datorită timpului de reacție adesea lung, setarea timpului de lucru la câteva ore este alt aspect important. Comparativ cu moarile tradiționale cu bile planetare, moarile hibride au avantaje unice în aplicațiile mecanochimice, permițând analiza spectroscopică RAMAN in situ.

Specificații:

MAX-mill Amestecător criogenic de performanță ridicată

Domenii de aplicare: |

agricultură, chimie, materiale sintetice, medicină, geometaliere, electronica inginerescă, materiale de construcție, resurse mediului înconjurător, sticlă, ceramici, bio alimente |

Caracteristici ale eșantionului: |

dure, medio dure, molde, fragile, elastice, fibroase |

Principiu de macerare: |

forța de impact, forța de frecare |

Setarea vitezei: |

180rpm la 2100rpm |

Timpul obișnuit de măcinare: |

30s - 2min |

Platformă de măcinat: |

2 |

Dimensiunea alimentării: |

setează în funcție de specificațiile adaptatorului |

Dimensiunea particulelor de ieșire: |

~5 µm |

Diametru măcinător: |

0.1-30mm |

Metodă de măcinare: |

măcinare secă, măcinare umedă, măcinare frozată |

Material adaptator: |

POM/nylon/aluminiu alianță |

Material tub măcinător: |

PTFE/oțel inoxidabil/zirconiu/agate |

Putere nominală: |

500W |

Descriere electrică: |

AC200~240V 50/60Hz |

Dimensiuni externe: |

L 530 * l 350 * Î 311mm |

Capacitate de eșantioane: |

96 * 2ml / 64 * 2ml / 48 * 2ml / 16 * 2ml / 10 * 5ml / 2 * 15ml (tub de măcinat personalizat) / 2 * 25ml (tub de măcinat personalizat) / 2 * 50ml (tub de măcinat personalizat) / 8 * 50ml (tub de măcinat standard) |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH