Industrial planetary ball mill: the core tool for industrial grinding

Industrial planetary ball mill: the core tool for industrial grinding

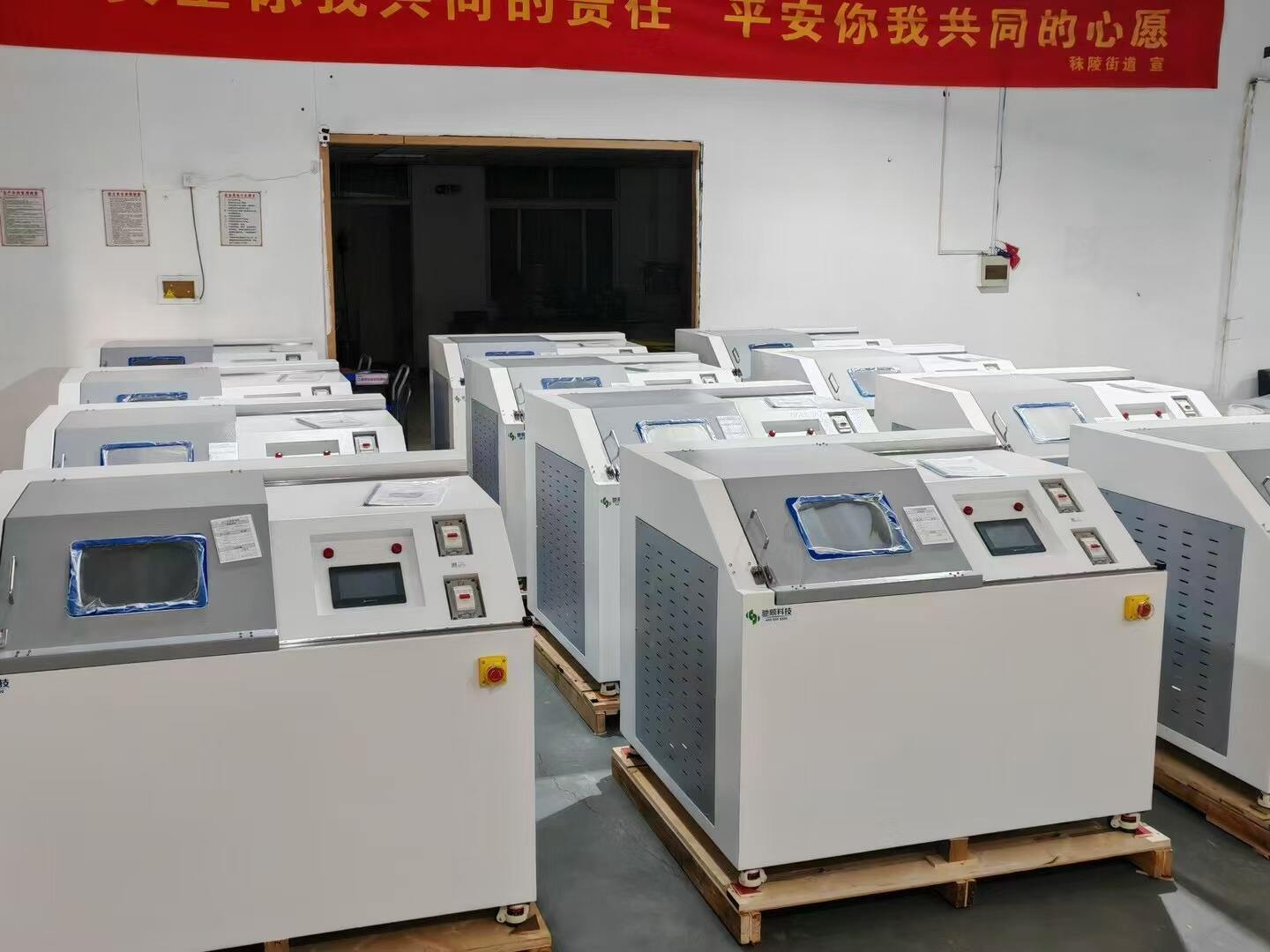

In the vast field of industrial production, fine processing of materials is crucial, and industrial planetary ball mills are the key equipment to achieve this goal, widely used in many fields such as chemical engineering, mining, and new materials.

The working principle of industrial planetary ball mills is based on unique planetary motion. The equipment is driven by a central spindle to rotate multiple grinding tanks around it, while each grinding tank also rotates at high speed on its own. This composite motion mode causes the grinding medium (such as grinding balls) to generate complex and intense motion trajectories inside the tank, exerting strong impact, shear, and friction forces on the material. Under the synergistic effect of multiple forces, materials can be crushed to extremely small particle sizes in a short period of time, achieving efficient grinding operations.

Its structural design is exquisite and practical. The sturdy body is the stable foundation of the entire device, ensuring that there will be no displacement or shaking during high-speed operation. The central spindle is made of high-strength materials, which can withstand huge torque and ensure smooth orbital motion. Grinding tanks are usually made of wear-resistant and corrosion-resistant materials, such as stainless steel, zirconia, etc. Suitable materials can be selected according to the characteristics of different materials to avoid material contamination.

In the chemical industry, it can grind various chemical raw materials to the required particle size, providing assurance for the production of high-quality products such as coatings, plastics, rubber, etc. In the mining industry, it is used for crushing and beneficiation of ores to improve their utilization efficiency. In the research and development of new materials, it is indispensable to help researchers prepare nanomaterials with special properties.

Precaustions: There are many precautions to be taken when using industrial planetary ball mills.

Before starting up, carefully check whether all components of the equipment are securely installed and whether the lid of the grinding tank is well sealed to avoid material leakage. At the same time, it is necessary to ensure that the ratio of grinding medium to material is reasonable. If the ratio is not appropriate, it may affect the grinding effect and even damage the equipment.

During the operation of the equipment, operators must not leave their posts and closely monitor the operating status of the equipment, such as the current and temperature of the motor, as well as whether there are any abnormal noises and vibrations. Once an abnormality is detected, the machine should be stopped immediately for inspection and troubleshooting before resuming operation.

After shutdown, it is necessary to clean the equipment in a timely manner, especially the grinding tank and grinding medium, to prevent material residue from causing corrosion or affecting the next grinding effect. Regularly maintain the equipment, such as adding lubricating oil to the bearings, checking the wear of transmission components, and replacing vulnerable parts in a timely manner to extend the service life of the equipment.

Recommended Products

Hot News

-

Chishun High Energy Ball mill:Help Starting New Era of Solid State Batteries

2025-03-29

-

Industrial planetary ball mill: the core tool for industrial grinding

2025-02-05

-

Pulverizer80 started it serving the OXFORD SUZHOU CENTRE FOR ADVANCED RESEARCH

2024-12-22

-

Invitation of Analytica China 2024

2024-11-10

-

CHISHUN AT THE ARABLAB LIVE 2024

2024-09-30

-

Precautions for using and installing vacuum glove box

2024-02-04

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH