Precautions for using and installing vacuum glove box

summarize

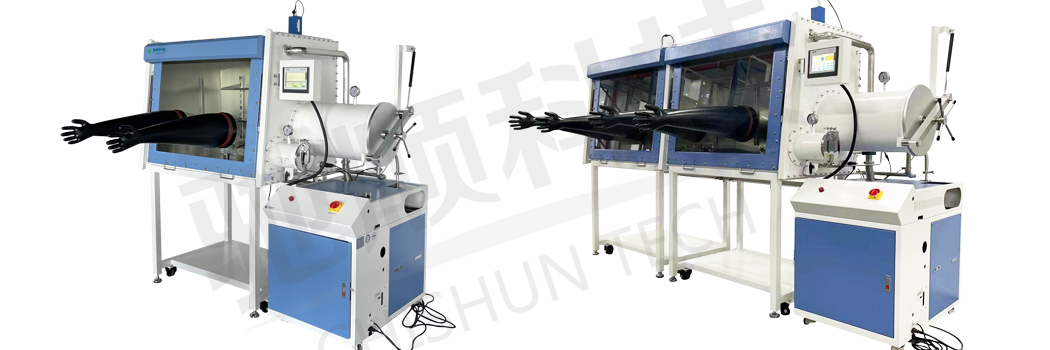

The ChiShun Technology glove box system is a fully enclosed system that can effectively remove water, oxygen, and organic gases. Its main function is to remove O2, H2O, and organic gases. The working gas inside the glove box is enclosed and circulated between the box and the purification column (water oxygen adsorber) through pipelines, circulating fans, etc. under the control and monitoring of PLC. When the working gas cycle passes through the purification column, its moisture and oxygen are adsorbed and then returned to the box. As the cycle time goes on, the water and oxygen content in the working gas in the box gradually decreases, ultimately reaching the indicator of less than 1ppm. After a certain period of circulation, the purification column will adsorb and saturate, and can be regenerated and reused. Widely used in ultra pure environments without water, oxygen, and dust.

Product features

Simple: Humanized design operation window, intelligent HMI human-machine interface, convenient operation;

Safety: High sealing fully protects the safety of personnel and samples;

Efficient: Integrated design improves equipment efficiency;

Energy saving: frequency conversion control operation;

Main uses and scope of application

A glove box is a laboratory equipment that charges high-purity inert gas into the box and circulates to filter out the active substances inside. Also known as a true empty glove box, inert gas protection box, etc. The main function is to remove O2, H2O, and organic gases. Widely used in ultra pure environments without water, oxygen, and dust, such as lithium-ion batteries and materials, semiconductors, supercapacitors, special lamps, laser welding, brazing, material synthesis, OLED, MOCVD, etc. It also includes biological applications, such as anaerobic bacterial culture, low oxygen cell culture, etc.

Environmental conditions for use

Room temperature: minimum+15 ℃ to maximum+30 ℃ (due to different loads, the requirements for external temperature also vary. Please pay attention to the temperature of the fan barrel not to be too high, and if necessary, install air conditioning and water cooling devices.);

Ground: sturdy and flat

The minimum distance between the non working surface of the equipment and the wall or other objects is 600mm;

The working area of the equipment needs to reserve a minimum width of 800mm to ensure sufficient operating space.

Impact on the environment and energy

Danger: The glove box uses high-purity inert gases such as argon, nitrogen, and helium; Prolonged exposure to high-purity inert gases can affect human health. Before use, ensure the sealing of the equipment and gas source. Please be careful when operating the equipment.

matters needing attention

1. Connect the regeneration gas pipeline to the outdoor or ventilation pipeline;

2. The exhaust port of the vacuum pump is connected to the outdoor or ventilation pipeline;

3. The room is in a dry and ventilated state;

4. Pay attention to the amount of gas used in daily life to avoid leakage.

Product structure and working principle

The glove box cycle is a closed loop, driven by a fan, where the gas inside the box passes through the purification column in the purification system and then returns to the box. After a long cycle, the purification column gradually absorbs trace amounts of water and oxygen in the box.

Main components

This glove box system mainly consists of the following parts:

1. Main box

2. Purification system

3. Water cooling (optional)

4. Large transition cabin

5. Small crossing cabin

6. Control system

Attention: Set the pressure correctly according to the requirements. If the pressure is too high, it will damage the system, and if the pressure is too low, the system will not operate;

Danger: Due to the use of inert gases in the equipment, there is a risk of suffocation. The cleaned exhaust must be discharged outdoors! Please strictly comply.

Quick cleaning

Preparation: Working gas: Prepare gas from ≥ 5 40L steel cylinders, with each cylinder containing approximately 4000L of standard gas and a gas content of ≥ 99.999%;

Purpose: To replace the air or other gases in the glove box that do not meet the requirements, so that the water and oxygen content inside the gloves is less than 100ppm;

Step: Click the "Clean" button on the touch screen to enter the cleaning settings interface, set the time and pressure in sequence, and then click OK to start cleaning.

loop

The glove box cycle is a closed loop, driven by a fan, where the gas inside the box passes through the purification column in the purification system and then returns to the box. After a long period of circulation, the purification column gradually absorbs trace amounts of water and oxygen in the box, ensuring the stability of the system through uninterrupted circulation and economically purifying the gas.

Attention: The glove box should be cleaned with working gas until the water oxygen content is less than 100ppm, and the circulation should be started. Excessive water oxygen will damage the purification system. When using a glove box, the circulation mode must be kept on, only in this way can the gas inside the box continuously maintain a water oxygen content of less than 1ppm.

Recommended Products

Hot News

-

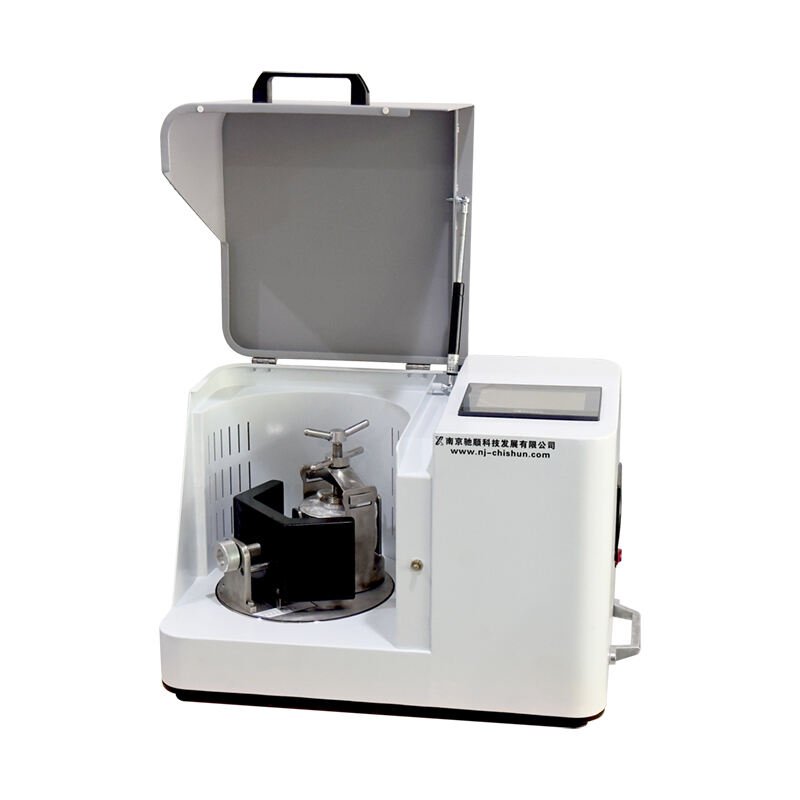

Chishun High Energy Ball mill:Help Starting New Era of Solid State Batteries

2025-03-29

-

Industrial planetary ball mill: the core tool for industrial grinding

2025-02-05

-

Pulverizer80 started it serving the OXFORD SUZHOU CENTRE FOR ADVANCED RESEARCH

2024-12-22

-

Invitation of Analytica China 2024

2024-11-10

-

CHISHUN AT THE ARABLAB LIVE 2024

2024-09-30

-

Precautions for using and installing vacuum glove box

2024-02-04

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH